I practical kat Zara Foodstuff Industries, JB..nk further detail bout this company..visit: http://zarafood.com.my/

Here the story of Zara’s goes....

It had been 3 weeks here and I’ve started my work since the 1st day there.. 4 your info..i’ll be placed in QA dept along the LI period...ONLY...so..its all about QA n food technologist duties..n i’m the only practical student in this dept..huwaaaa.....1st day..no production due to sugar shortage (gula naik harga kan..ish2..)n got my training module from the supervisor, Mr Fathuddin..hmm..in the module OBVIOUSLY STATED the TASKS...huhu..well..there are some task given..n i’ve to complete them all before end of LI..

The tasks are:

1. HACCP documentation

2. On job training report on specific topics: - fermentation, microbiology lab, soy sauce, sri kaya n chilli/tomato sauce production and waste water treatment.

3. SPECIAL task..cant tell by now..later ya..=)

1st week:

Feel excited n anxious at the same time..huhu..being a lone ranger was a big challenge 4 me.but everything goes well..alhamdulillah..=)my QA manager, Mr Nazri , who was Prof’s student b4 is a strict person n wants me to make a full report on ‘behind of scene’ of the processes of all products..n the most important thing is I HAVE TO PRESENT AT THE END OF LI(industrial training) PERIOD..huwaaa..present alone..=p luckily I have a very generous supervisor who really do help me alot..

I start my 1st week with the introduction of Quality system ISO 9001, HACCP and 5S system that had been implemented. ..i hv to read n go thru all files n jotted down any info related to my tasks...huhu..very rajen la sekarang..=p

My day start with sample analysis on soy sauce and chilli/tomato sauce..n here is the place where i show my ‘talent’ to use all ‘gadgets’..huhu..its a COMPLICATED equiptment..hehe..they are: pH meter, refractometer, brinometer, salinometer , consistometer and viscometer..the parameters that has been use for quality assurance for all products are vary on all product:

Soy sauce: pH, brixs, salinity, specific gravity and temp, taste (i hv a good sensory for kicap masin n manis now..huhu..)

Chilli/tomato sauce: pH, brixs, taste, viscosity, consistency

Sri kaya: brix, taste and texture

I’ve also visit the fermentation area at the back area of factory..it’s very clean n systematic..as all the fibreglass used for ferment the ‘Koji’ are all well-oriented..the height of the fibreglass is 2 feet..so..kene panjat pakai tangga la ye..i did it very well n also been given a ‘chance’ to check the pH and specific gravity of bean water (brine solution+ koji) and ‘pegang’ koji yang dh ferment..

hmm..bau dia mmg xbest..tp okla..bacteria mmg la busuk kn..ngeee...

I’ve seen the A-Z process of fermentation n berkenalan with abg Nepal..huhuhu..abg Nepal tu tanya “Name what?” n berlangsungla interview session antara kami..huhu..xpe2..menarik..ni kire international relation ni..bgos2..=p

Anyhow..all workers gv a very detail explanation on the fermentation process ni...berulang kali tau..tak tau nape..maybe sebab i’m the only gal yg ade kat fermentation area tu..huhu..but..really appreciate it..they all terang technically but my beloved QA manager wants me to investigates the story behind..hmm..still got a lot works to do..CHAYOK!!!!=p

Overall..this week was very welcomed sbb keje x banyak lagi..huhu..n sempat celebrate bday my Group Chief Executive, Dato’ Hj Zulkifli..siap ade karaoke..best2 =)

2nd week came...=p wah...cepatnye mase berlalu..this week..i’m more focus to my 1st on-job training:fermentation..so..get ‘dirty’ with koji..Aspergillus oryzae...retort..brine solution...hmm..we all have been a good friends thou..=p sangat seronok sbb i can play with MICROBES!!!my fav...=)

And the best part of this 2nd week is run an analysis of Total Nitrogen for soy sauce products..best sgt2...deal with Kjedahltherm..best2..rase dah macam food technologist..berangan2 ni..huhu..i did an analysis on salty and sweet soy sauce n bean water analysis use 2 different catalyst..make a report n get use to the equipment was the best experiences..best sbb all preparation 4 experiment kene wat sendiri..prepare solution sendiri..carik method pon sendiri..mencabar..=) so..i’ve changed to a very independent person sbb kene wat semua sendiri no help from others but only can get guidance from my supervisor...so..its like i’m a super gal la..=p 1st experiment byk error..tp 2nd experiment..was PERFECT!!!=) no technical errors come from me..huhu...good job..=p report kne submit b4 end of this month..come on izen..wat report cpat..stop “facebooking’ ya...=p

3rd week goes smoothly.....

Macam biase..analyze samples..dah paham data recording system kat sini..so..trus buat without observation from my supervisor n his colleague..madam yanti..n they both mmg trust with my ability to conducts any task especially Total Nitrogen and Total Plate Count (TPC) experiment..

About TPC..mmg sgt best..deal with laminar-air flow..huhu..lame x jumpe..hihi..n autoclave..best..sbb dapat learn how to run autoclave..b4 this science officer yang run kan..skarang wat sendiri ya..huhu..best sgt2..tp malangnye my fav ‘gadget’ rosak..MICROSCOPE..tidakkkkkkkkkkkkk....but..what to do kan..terima la kenyataan ni..samples yg nak analyze gune microscope all been sent to external lab...sigh...=(

This week still ade wat microb experiment..tapi bukan experiment la..kene wat inoculum untuk starter for koji..further details later ya..=) menarik la wat inoculums ni..n this preparation method mmg cerewet sbb if ade wrong method...bacteria lain yg tumbuh and koji yg dihasilkan pon x bagus..so..kene byk b’sbar..baru blaja wat..xtau la hasilnya..kne tunggu 4 a few days..nnt saya bgtau hasilnya ya..=)

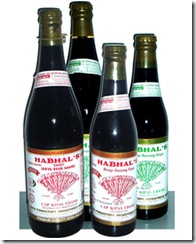

Lupe plak nk cite bhgian production sri kaya n chilli sauce..processnya xla complicated sgt..semua nya use machinery..xde manual..tp ade sket je yg manual...untuk implement HACCP mmg ade perubahan yg perlu dibuat..tp semua process boleh dikatekan ‘high-tech’..technical prob tu normal la..die ‘robot’ kn..maybe screw ade tercabot kot..huhu..hygiene pon ok..mmg menyenangkan hati..=) so..belila kicap kipas udang ye..tiada keraguan..huhu..

4th week..

Xabes lg..baru bermula..n this week minggu bersedih..minggu tudung putih...di atas kemangkatan almarhum DYMM Sultan Iskandar..kami rakyat jelata johor berkabung selama 7 hari..=( tp idup mesti terusssssssssss..=) this week best sbb tadi (isnin) baru je panjat tangki waste water treatment with height 20 feet..bestnye..dh lame x panjat tinggi2..berdiri kat atas tu dgn angin tiup sepoi2 bahasa..eh salah..tiup kencang..naseb baek x melayang(xleh pon..sbb lemak berlebihan..ish2..)kami (my supervisor n me) dh macam Leonardo di caprio ngn kate winslet dh..tinggal play lagu my heart will go on je..haha..bahaye2..jgn risau..i’m a good gal here..no naughty2...he’s getting married soon la..good2..=p

So people...those above are my stories kat ZARA...sbnarnye ni short version..xlarat nk cite the long 1..its about 11 pm now..got to go..till pen meet paper again..opss..correction..till fingers meet keyboard again..=)to all my fellow friends..good luck ya..n miss u guys so much...

N not forgetting..Prof, Mdm Liya n Miss nurul..tq 4 all supports and guidance..lots of love to all of u..miss UDM!!!!!!!!!mmmuaahhhhh..hihi..

entry ni dah ade kat blog Food Tech UDM:

mcm mn nk mhn li kat zara;s ek? ad ap2 requirement x??

ReplyDelete